3 Inches CNC Mandrel Tubing Benders Popular sells

- Model

- SB-75CNC-L

Item specifics

- Bending capability OD×WT

- Φ76.2×3.0 mm

- Bending speed

- Max. 120°/sec

- Feeding speed

- 1000 mm/sec

- Feeding accuracy

- ±0.1 mm

- Rotating speed

- 180°/sec

- Rotating accuracy

- ±0.1°

- Voltage

- 220V, 380V, 415V, 440V, 480V, 600V 3P

- Mandrel bending

- Ball Mandrel

- Wiper die

- Brass Wiper

Review

Description

CNC Mandrel Benders 3 inches Popupar Benders

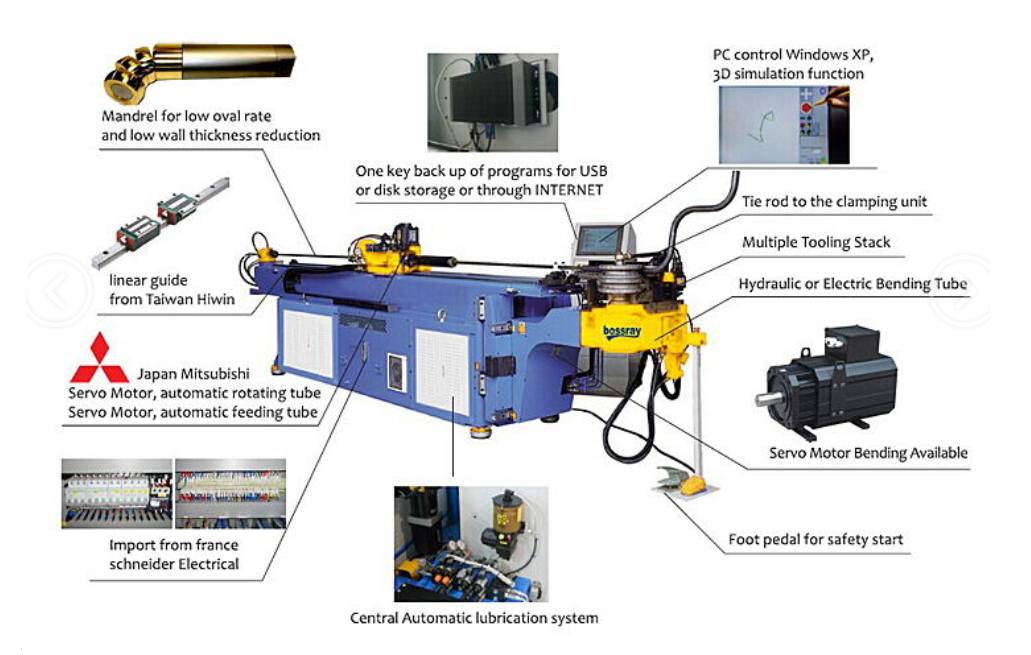

Bossray 75CNC Mandrel Benders is the advanced Tube Benders with multi-axis servo motor controlling and multi-layers mould function. The machine applys professional skills of industrial computer and CNC Pipe Benders into multi-axis servo motor and hydraulic servo driving. It can work automatically like feeding,rotating,changing moulds, reading drawings, editing and revising technical documents and correcting datas. What's more, working with robots, it also can loading and unloading automatically, testing pipes and revise technical datas and production procedures according to the test result. It can diagnose fault automatically, 3D pipe display and simulation,3D interference detection etc. It is the first choice for the field of Automotive, Motorcycle & ATV, Fitness GYM, Medical and Furniture, etc.

1-9 stacks tooling are optional.

75CNC Mandrel Benders Parameter

|

Model |

SB-75CNC-L |

|||

|

Bending capability OD×WT (carbon steel):

|

Φ76.2×3.0 mm |

|||

|

Bending radius: |

280mm |

|||

|

Bending angle |

0~180° |

|||

Max bending length with mandrel: | 3200mm | |||

Bending speed: | Max. 120°/sec | |||

Bending accuracy: | ±0.1° | |||

Feeding speed: | 1000 mm/sec | |||

Feeding accuracy: | ±0.1 mm | |||

Rotating speed: | 200°/sec | |||

Rotating accuracy: | ±0.1° | |||

Tools stack: | 1 or multiple | |||

Bending: | Electric Servomotor or Hydraulic | |||

Feeding/Booster: | Electric Servomotor | |||

Rotating: | Electric Servomotor | |||

Work head shift (horizontal): | Electric Servomotor option | |||

Work head shift (vertical): | Hydraulic /Electric Servomotor option | |||

System hydraulic pressure: | 14 MPa | |||

Packing size refer: | 4900×1050×1350mm | |||

Weight refer: | 3000kgs | |||

Video

3 Inches CNC Mandrel Benders Video

Providing the automatic functions of feeding, rotating, die exchanging, drawings reading, editing, file modifying,rebound data adjusting, automatic faults diagnosing and 3D display.

CNC Mandrel Benders Features and Advantages

- 1Bend-arm (C-axis) by Hydraulic / Servomotor

- 2Clamp die by hydraulic or servomotor; pressure die by hydraulic or servomotor.

- 3Carriage (Y-axis) by servomotor.

- 4With rear booster is driven by a servo motor.

- 5Collets (B-axis): rotation by servo motor, grip by hydraulic or servomotor.

- 6 With the roll bending function (PUSH BENDING), can make a big radius by rolling.

- 7Tooling shift: motion up-down by hydraulic or servomotor with brake; left-right by servomotor.

- 8PDA (pressure die assist): by hydraulic or servomotor.

- 9Automatic moving parts lubrication systems.

- 10Standing pedestal, serves emergency stop, double-hand startup, and remote control.

- 11Industrial PC (windows system) assorted with touch screen display, 3D preview, remote control, 3D bending simulation, and collision prevention.

OPTION

- 1Multi radius

- 2Left and right direction bending

- 3Punching device

- 4Cutting device

- 5Safety fence

- 6Safety mat or Light curtain protection

- 7Bend 1.0*D radius or more tight radius

- 8Fan / Water / Oil cooling system

- 9Robot loading and unloading systems

- 10Safe blanket / Infrared alarm device

- 11SIEMENS 3D convert

- 12Electric power supply transformer

- 13Quick tooling change

- 14Special tooling design and brass mandrel