CNC Fully Automatic High Precision Fiber Laser Cutting Tube Machines

- Model

- FLT-6020HT

Item specifics

- Cutting diameter

- 20 to 200 mm

- Maximum tube weight

- 500 kgs

- Laser type

- Fiber Laser

- Laser source

- IPG RAYCUS MAX

- Cutting Speed

- 80m/min

Review

Description

CNC Fully Automatic High Precision Fiber Laser Cutting Tube Machines

Bossray CNC Fiber Laser Metal Tube Cutting Machines for

Save time and reduce the number of components.

Make tubular frames and metal structures that are more precise and faster to assemble.

Complete your part in one programming step, in one machining step, and on one system.

You can laser-cut tubes of any circular, rectangular, open or special cross-section as well as extrusions and profiles.

CNC Laser Tubes Parameter

|

Model |

FLT-6020HT |

|||

|

Effective Tube Cutting Length:

|

6000mm |

|||

|

Laser Output Power: |

6000W / 3000W / 1500W |

|||

|

Effective Round Tube Cutting Diameter:

|

Φ20-200mm |

|||

Effective Square Tube Cutting Diameter: | 15x15, 150x150 | |||

Rectangular tube Edge Length: | 15x150 | |||

X/Y-axis positioning accuracy: | 0.05mm/m | |||

X/Y-axis repositioning accuracy: | 0.03mm | |||

X axis maximum speed: | 140m/min | |||

Y axis maximum speed: | 100m/min | |||

Rotating accuracy: | ±0.1° | |||

Video

CNC Fully Automatic High Precision Fiber Laser Cutting Tube Machines Video

Lasertube, your new competitive edge.

Machine base introduction

✔ 20mm thick metal sheet forming.

✔ Italian COLGAR machine milling boring.

✔ Machine body net weight 8.5 tons.

✔ Machine error accuracy 0.02mm.

✔ With 24 hours quenching process.

✔ Cutting speed 80m/min.

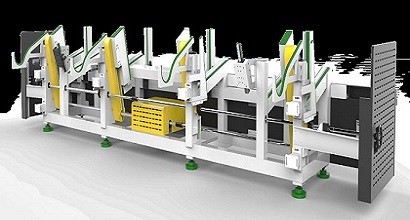

Automatic Loading System

✔ Automatic for round tubes and manual for square tubs;

✔ Round tube diameter 20-120mm

✔ Interval time 20-25 seconds;

✔ Load bearing of single tube 80 Kg.

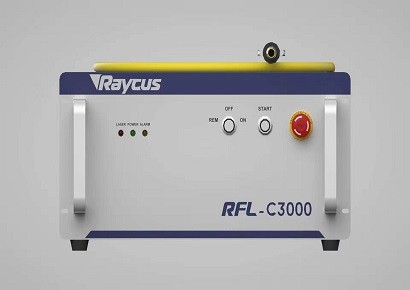

Raycus 3000w Laser source

✔ High electro-optical conversion efficiency

✔ Altitude stress-resisting capacity

✔ Tube cutting efficiency

✔ Customized output fiber length

✔ Maintenance-free operation

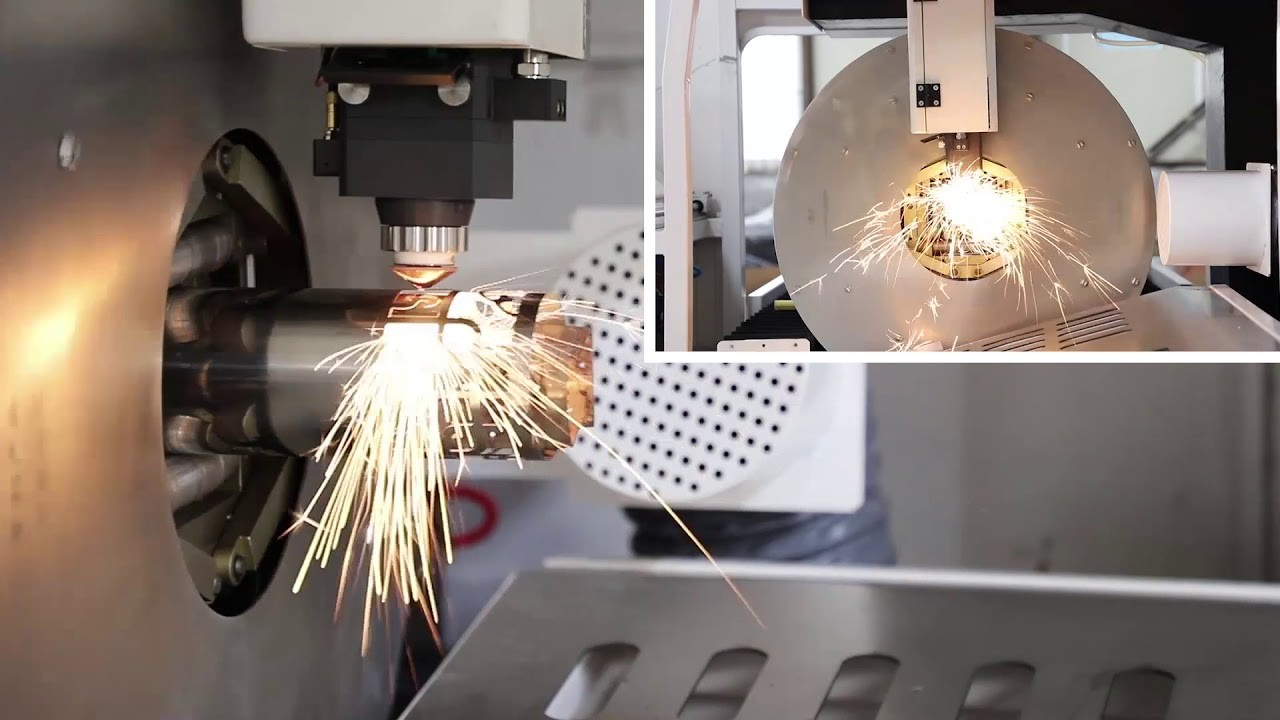

Raytools BM111 3D TUBE laser cutting head

✔ Sealed structure

✔ Focal length adjusting system

✔ Protective window with drawer

✔ Focal length:75mm/100mm

✔ Auto focus

✔ Air pressure for assit gas:≤25bar

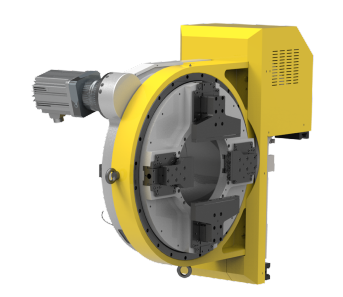

Double-chucks with Upgraded Processing Ability

✔ Longer: achieve 6000mm

✔ Heavier: achieve 500Kg

✔ Rectangle/Round Tube Clamping Range: 20-200mm

Fully-sealing and Professional Chucks

Avoid dust to enhance chuck's working life.

Whole-track Rectangular-circle Chucks

✔ More convenient for loading, without processing pause.

✔ Achieve types diameters of single rectangular/round/I-beam/H-beam

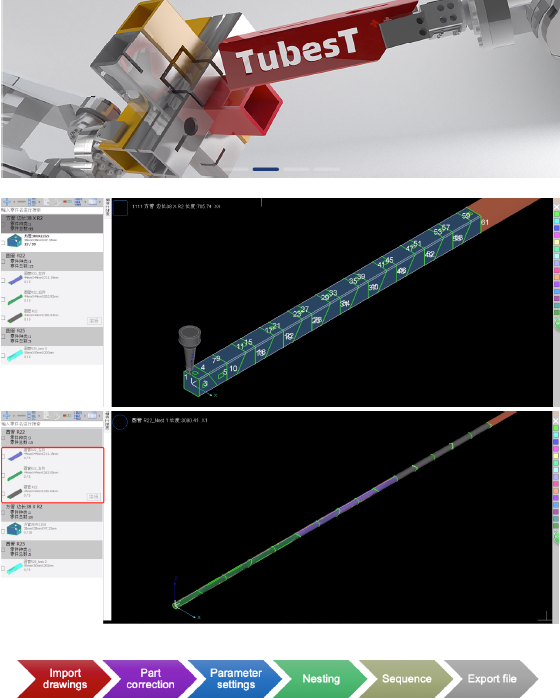

Design of parts and frames in a three-dimensional graphical CAD/CAM environment designed to exploit every performance margin of the Bossray Lasertubes.

Libraries of functions that speed up and simplify design on the tube.

Accurate batch time and cost estimates for a detailed estimate.

Remote planning and real-time monitoring of work in progress.

All this and more makes a difference every day in terms of being able to make full use of a laser cutting system, reducing unproductive downtime times and eliminating waste.

A choice of value also involves software.

CNC Lasertube Features and Advantages

- 1Gas-saving Nozzle with Steady Flow

- Cutting performance and efficiency are improved by maintaining gas flow steady with little turbulence.

- 2Bossray Lightning

- The lightning-quick piercing process combined perfectly with BossrayGenius completes the whole piercing just during the laser cutter head moves down on Z-axis.

- 3Angle Steel and Channel Steel Cutting

- Angle steel and channel steel cutting are standard with no need for additional installation.

- 4Four-side Edge Searching, Higher Precision

- Optimized edge searching method and algorithm guarantee higher cutting precision and better steadiness of the laser cutter.