Wholesale CNC Tube Benders Die Sets - Onsite Training, Spares, and Customized Services

Item specifics

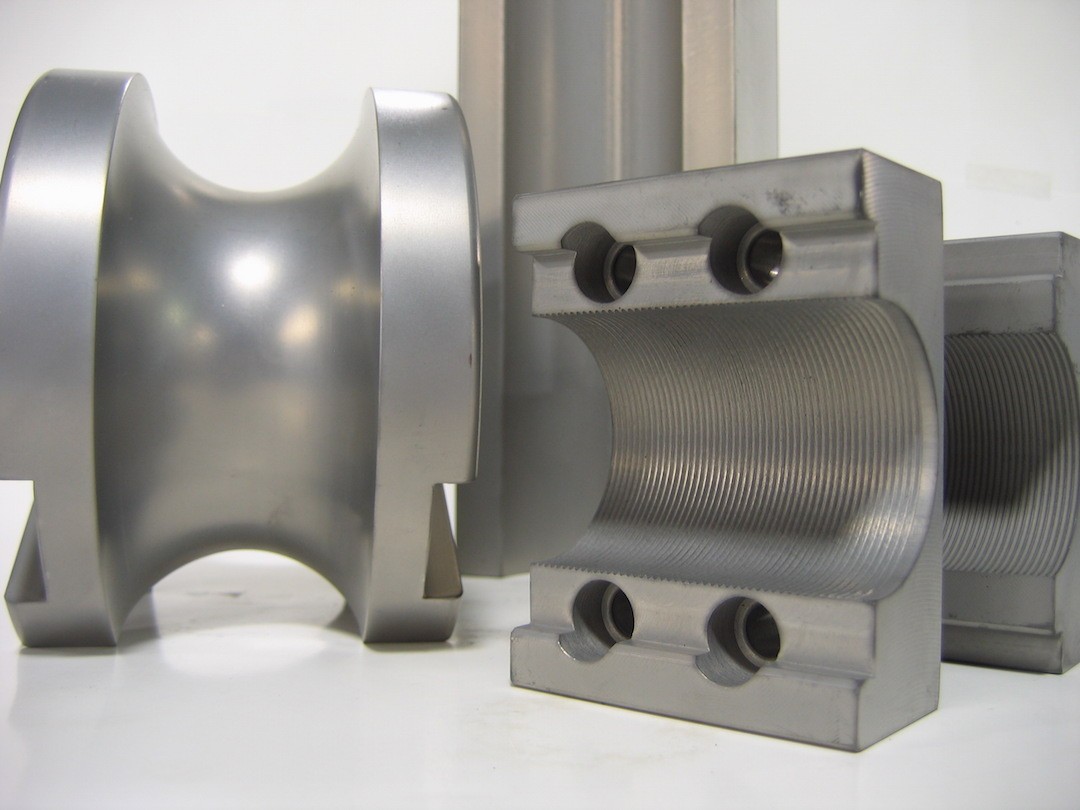

- Bend die

- CLR x 2

- Clamp die

- Pipe outside diameter

- Pressure die

- Pipe outside diameter

- Ball Mandrel

- Pipe inner diameter

- Wiper die

- Pipe outside diameter

- Collet

- Pipe outside diameter

Review

Description

BOSSRAY BENDER TOOLING SYSTEMS

What was started as an integration strategy to stay in control of the processes can easily become a nightmare. The reality is that when problems develop, parts fail to ship or the quality of them regularly fails to meet the needs, even a qualified and capable outside source has its hands tied to come in and offer more than a quick band aid on the fly.

Bossray Rotary draw bending is by nature more involved and complicated but subsequently the most versatile. It is the only method that is suitable to produce high quality wrinkle free bends in tight radius thin wall tubes. It is by far the most used for any application where support is needed to control the stretching and compression of material and simultaneously prevent the tube from collapsing.

SPECIFY

Tube O.D. and Wall Thickness

Center Line Radius CLR

Make and Size of Benders

Degree of Bending

Rotation of Bender

Interlock Dimensions

Desired Production

As one of the world's elite bending die makers, Bossray supplies the entire package for rotary-draw tube and pipe-bending. Our dies are manufactured with CNC machining, the most advanced machining technology in the industry, making our new generation of Bossray die sets unsurpassed in fit and finish. Whether you need bend, clamp, or pressure dies, Bossray has what you need. Plus, these tube and pipe-bending dies are tough!

More often than not we would move to a type 6 design and be done with it. As we are building a system to ensure optimal compatibility we are going a slightly different route. It has been found that using the attributes of both these dies in a hybrid design can bring about the most versatile and strongest platform This will be the first design point we will build on. First however we need to get some other basics considered. There are several schools of thought regarding Interlocking dies that should be factored in as well at this point.